- Description

-

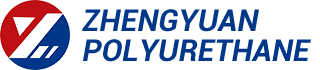

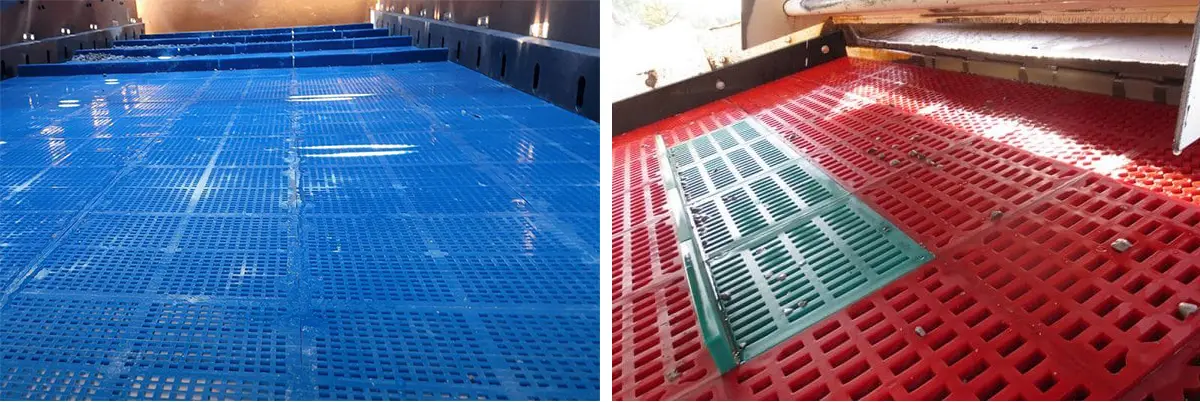

Flip-flow screens, also known as flip flop or elastic mesh screens, are machines designed to efficiently screen sticky, wet, and other difficult materials. Flip-flow screens are used in a number of industries to separate everything from aggregate and minerals to inhomogeneous recyclables, construction waste, and biomass.

Flip-flow screens work through the combination of a double vibration principle and a flexible polyurethane-type screen media. The dual-vibratory forces work to apply linear acceleration to the materials traveling across the screen. Vibrations are simultaneously applied to the elastic screen, which rapidly stretches and relaxes. The stretching and relaxing of the screen transfers energy to the material, causing it to “jump” or “pop”. This secondary vibration, in turn, enhances the separation of materials.

n addition, both as a result of their polyurethane screen and streamlined design, they’re less prone to mechanical wear and tear, and are generally easier to maintain. This latter point is of importance when screening difficult materials.

Wet and sticky materials in particular, like consumer recyclables and biomass, can clog and blind conventional screen media. The elastic mesh media used in flip-flow screens is ideal for these materials. However, the media is as effective for other common materials from glass and scrap to fine-grained minerals and slag.

Key words:

Polyurethane Filp Flow Screen

Yantai Zhengyuan Polyurethane Co., Ltd., established in 2007, is a leading manufacturer of polyurethane products, specializing in providing high-quality polyurethane material solutions.

Contact Us

Address: 4, Zhichunan Road, Zhifu District, Yantai, Shandong Province, China

Zip: 264000

Wechat/Mobile/Whatsapp:

+86-13276382621

Email ID: bill@zhengyuanpu.com

Products